(Photo source: Internet)

YiNGUAN can provide large-stroke, high-stiffness prestressed actuators for coating film thickness control of slot coating equipment, ensuring faster response and higher-precision coating film thickness.

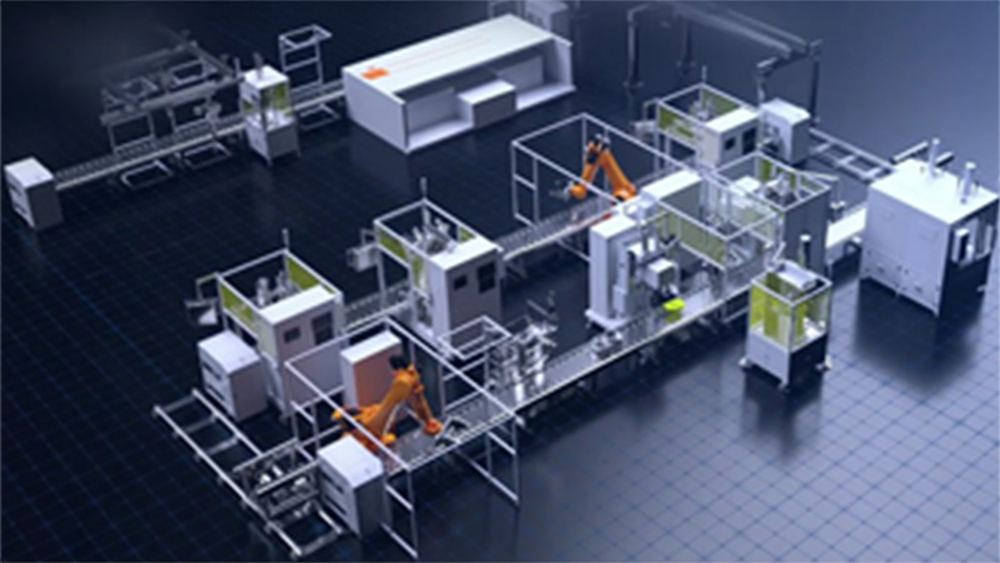

Coating technology can be used in many fields and scenarios, mainly including lithium battery pole piece coating, fuel cell electrode coating, perovskite solar cells, thin film transistor coating, Fan-Out Panel Level Packaging, organic light-emitting diodes (OLED), etc.

Common coating methods can be mainly divided into blade coating, roll coating and extrusion coating. Compared with other coating methods, slot extrusion coating has many advantages, such as fast coating speed, high precision, and uniform wet thickness; the coating system is closed to prevent contaminants from entering during the coating process, and the slurry utilization rate is high, it can keep the properties of the slurry stable and can carry out multi-layer coating at the same time. It can adapt to different slurry viscosity and solid content ranges, and has stronger adaptability than the transfer coating process. It is also the coating method mainly used in the front-end stage of lithium batteries.

Slot extrusion coating technology was gradually developed with the development of the modern electronics industry. It is mainly coated through slot extrusion and can obtain higher-precision coatings. Slot extrusion coating means that a certain flow of slurry enters the inner cavity of the die from the feed port of the extrusion head and forms a stable pressure. The slurry finally flows out evenly at the slot outlet of the die and is coated on the Material.

The overall performance of slot extrusion coating is excellent, but the technical and equipment accuracy requirements for the core components of the high-precision slot die coating are relatively high. At present, the slot extrusion coating die mainly realizes the slot gap adjustment process through three methods: bolt adjustment, micrometer adjustment or micro-step motor adjustment. The method of bolt adjustment to control the slot gap cannot achieve rapid adjustment of the coating process and precise control of the slot size due to bolt thread wear, deformation, jamming, etc. Moreover, the bolt adjustment process relies heavily on the operator's experience, and the adjustment has hysteresis. The method of adjusting the micrometer to control the slot gap also has the problem that the adjustment process relies on the experience of the operator, and the adjustment has hysteresis; and because each micrometer structure is individually connected to an adjusting piece, there is a height difference between the adjusting pieces, causing problems in the coating process such as streaks and dark marks pose the risk of surface density control failure. When using a micro-step motor to control the slot gap, due to the crawling phenomenon of the micro-step motor during high-resolution control, stroke mutations occur, which makes stripes, dark marks and other defects prone to occur when the coating process is frequently adjusted, affecting the areal density consistency. The piezoelectric ceramic coating die uses a piezoelectric ceramic control module to accurately control the discharging gap of the coating slurry, reducing dependence on the operator's experience. The piezoelectric ceramic actuating end is directly driven by the micro-deformation superposition of the piezoelectric ceramics, controlled by the input voltage, has a sensitive response and will not cause stuck or crawling problems, and the overall structure of the adjusting piece has no seams or faults, and the coating slurry discharge gap formed has a smooth and neat interface, and the extruded coating thickness is more uniform, which can effectively eliminate coating quality defects such as streaks and dark marks, and ensure the consistency of surface density during the coating process.

YiNGUAN can provide large-stroke, high-stiffness piezoelectric ceramics & control modules, which are used to control the discharge gap of the slot coating die to ensure faster response and higher-precision coating film thickness.

The stacked piezoelectric ceramic actuator adopts the structure of stacked piezoelectric ceramic sheets, and realizes the superposition output of the response displacement of multiple layers of ceramics under electrical signal excitation, with the maximum displacement reaching 180 μm.The company has rich product specifications to match different die head specifications. The company can provide a complete set of piezoelectric ceramic control modules, which can achieve rapid positioning, installation, and convenience and flexibility in model change, disassembly, and maintenance. At the same time, according to the specific needs of customers and specific application scenarios, the company integrates strain gauges to achieve closed-loop control, and configures self-developed and adapted drives to achieve the technical and cost advantages of the product portfolio.

Our company has four domestic service centers in Shanghai, Suzhou, Guangzhou and Chengdu, which can quickly respond to the needs of customers across the country for technical upgrades, project development and maintenance, etc.

At present, the company's piezoelectric ceramics have achieved mass production, completed market verification in areas such as lithium power battery pole piece coating, and provided stable and continuous supply.