MFC, or Mass Flow Controller, is a precise measuring and controlling instrument of fluid quality flow, being the key functional unit to ensure process accuracy and product consistency.

According to QYResearch's latest research report, it is expected that the global semiconductor flow meter market size will reach USD 5.3 billion in 2029, with a compound annual growth rate (CAGR) of 8.2% in the future several years.

Currently, gas flow meters are the most significant sub-products, accounting for approximately 58% of the market share.

MFC plays an important role in various stages of semiconductor processing: In processes like etching, deposition, it is used to monitor and regulate mixture gas flow rates and vacuum levels in real-time, ensuring accurate mixture gas proportions. In material cleaning stages, it controls nitrogen gas flow rates to ensure cleanliness and drying effects. In cleanroom infrastructure, it stabilizes environmental gas purification and airflow. To guarantee semiconductor manufacturing process stability and product quality, MFC products typically require High precision、High stability、High reliability and Rapid response. According to industry applications, currently, deposition equipment is the largest demand source, accounting for approximately 36.1%; etching equipment accounts for approximately 29.4%; RTP/ Furnace / Reactor equipment accounts for approximately 16%; cleaning equipment accounts for approximately 10.4%; ion implantation equipment accounts for approximately 8.03%.

In recent years, Japanese Horiba and American Brooks and other industry leaders have successively launched piezoelectric ceramic valves and semiconductor-level MFC products that improve response speed while significantly reducing long-term performance degradation, heat and leakage issues. Research shows that the Asia-Pacific region is the largest market for semiconductor flow meters, with domestic companies making good progress in production to meet high-precision, high-reliability and rapid-response demands.

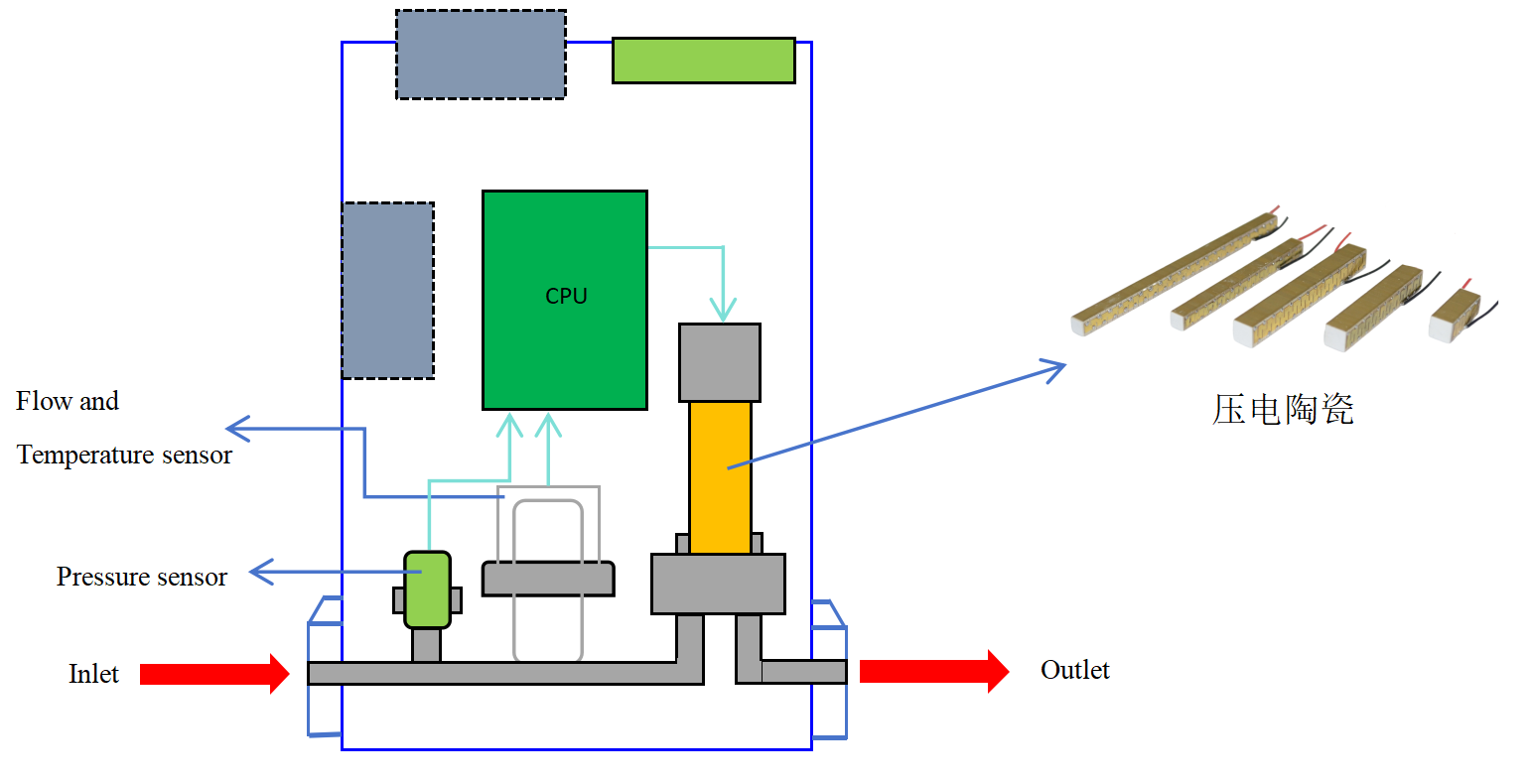

Piezoelectric valves are core control components of MFCs, forming a closed-loop system with flow sensors to dynamically adjust gas flow. Compared to current domestic mainstream electromagnetic valves, piezoelectric valves respond quickly, have high control accuracy, and low power consumption and heat noise.

(Mass Flow Controller’s structure)

Piezoelectric Actuators for MFC Mass Flow Controllers

YiNGUAN provides MFC core components, including piezoelectric actuators in a stacked ceramic design, which has a response time of sub-milliseconds and nanometer-level resolution to ensure faster response and higher accuracy control. YiNGUAN's self-researched and produced stacked ceramic can generate a large driving displacement at low voltage, while the all-metal sealed piezoelectric actuator has been batch-produced with excellent performance and consistency.

The company's piezoelectric ceramics have achieved mass production and offer a wide range of product specifications and varieties to match different Piezoelectric valves structural designs.

To meet clients' customized integration requirements, YiNGUAN can customize packaging dimensions, voltages, strokes, and metal terminals, ensuring mechanical stiffness and stability to ensure the reliability and long-term performance of the Piezoelectric valves.