Complex time-variable atmospheric conditions can cause high-frequency random disturbances to precision optical systems during light transmission, resulting in decreased image clarity and laser focus shape, significantly reducing the effectiveness. Utilizing wavefront correctors can dynamically compensate for spatial light beam wavefront aberrations, thereby significantly improving image detection accuracy and laser transmission performance.

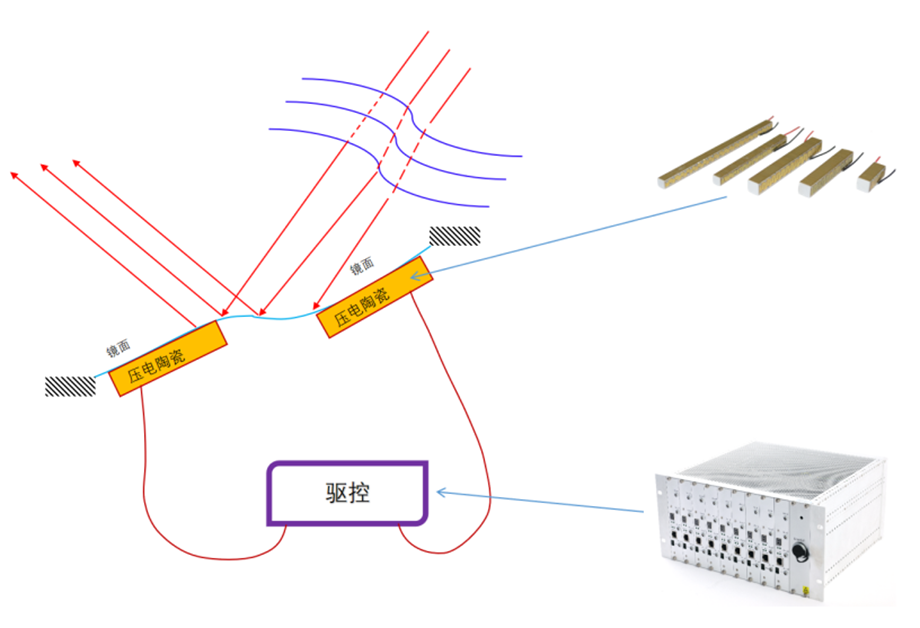

Typical wavefront correctors include liquid crystal spatial light modulators, mechanical deformable mirrors and piezoelectric deformable mirrors (driven by ceramic actuators). Among them, piezoelectric deformable mirrors have the highest response frequency, up to several kilohertz, and can withstand high power density lasers, with broad application prospects.

Deformable Mirrors (DMs) are key components in adaptive optical systems that achieve wavefront correction, and their performance directly determines the system's ability to correct wavefront aberrations.

Currently, they are widely used in astronomical observations, biomedical microscopy imaging correction and laser processing beam shaping. As the use of DMs increases, the demand for dynamic and static control accuracy and speed in optical systems and DMs themselves also increases. To improve the correction accuracy of DMs, it is necessary to change their inherent properties and use control algorithms for DM control.

At the same time, based on the latest market trend analysis, it is predicted that the global DM market will maintain stable growth in the next few years and reach a noticeable scale in the future.

According to the structure form and driving mode of PZT or barium titanate ceramic actuators, piezoelectric mirrors can be further divided into:

Piezoelectric Stacking Mirror

Piezoelectric Plate Mirror

MEMS Piezoelectric Micro-Mirror

Piezoelectric Plate Mirrors use a single-layer or double-layer thin plate-shaped piezoelectric ceramic actuator as the driving unit, with advantages such as ultra-lightweight, high integration, simple manufacturing process and low cost. However, when working at high frequencies under control voltage excitation, it may be affected by mechanical resonance, displacement-voltage phase delay, etc., making it difficult to achieve high shape control accuracy.

Piezoelectric Stacking Mirrors have complex manufacturing processes and high costs.

When driving piezoelectric mirrors using continuous surface control, each ceramic actuator corresponds to a high-voltage amplifier circuit, so the structure size, drive capability, signal quality and cost of high-voltage amplifiers need to be fully considered in the design of piezoelectric mirror systems.

According to working principles, high-voltage amplifier circuits can be divided into two types:

Linear Power Amplifier Circuit

Switching Power Amplifier Circuit

Switching power amplifier circuits have advantages such as small power loss and heat generation, but require Pulse-Width Modulation (PWM) to output power, which needs signal filtering and reconstruction, resulting in large voltage ripple and poor frequency response.

In contrast, Linear Power Amplifier Circuits have advantages of good linearity, high stability and low noise due to the transistor operating in the linear region. However, they have disadvantages such as high power consumption and low efficiency.

Piezoelectric Department of YiNGUAN Focuses on the research, development, manufacturing and sales of precision positioning actuators and motion systems; which also is one of the few domestic high-tech enterprises that owns a complete product chain from piezoelectric ceramic materials to piezoelectric ceramic motors to Nano precision piezo-motion tables. The company has rich experiences in industrialization.

YiNGUAN provides stacked piezoelectric ceramics with millisecond response time and nanometer resolution, maximum displacement up to 180 micrometers, and resonant frequency up to 250 KHz, ensuring quick response and high precision control. YiNGUAN's self-developed stacked piezoelectric ceramics can produce large driving displacements at relatively low voltage.

The company provides comprehensive piezoelectric ceramic control systems for fast installation, replacement and maintenance. To meet customers' customized integration requirements, YiNGUAN Semiconductor can customize package sizes, voltages, travel ranges and metal end connectors, ensuring mechanical stiffness and stability, guaranteeing the reliability and long-term performance of the mirror system.

For different customers' special requirements, YiNGUAN can provide customized packaging dimensions, voltage, stroke, and metal parts to meet mechanical stiffness and stability requirements.

Meanwhile, the company integrates strain gauges to achieve closed-loop control for customers' special needs. Self-developed drivers and controllers are optional to achieve product’s technology and cost advantages.