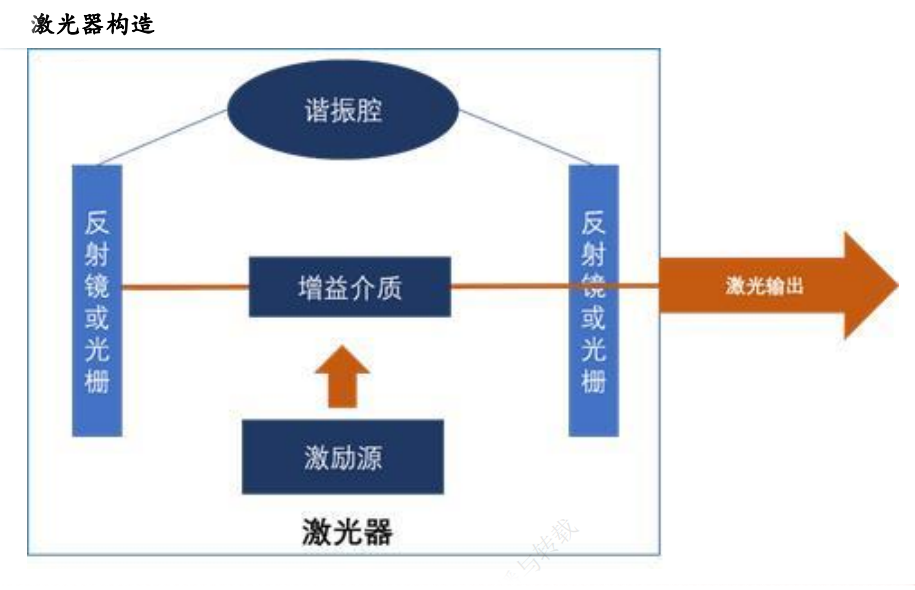

Laser is a device that uses stimulated emission to produce visible or invisible light, with complex structures and high technical barriers. It is composed of a large number of optical materials and components, occupying the central position in the entire laser industry chain. The main parts include: Optical System, Power System, Control System and Mechanical System. Optical System mainly consists of Pump Source (Excitation Source), Gain Medium (Working Substance) and Cavity etc. optical device materials.

Pump Source (Excitation Source) provides energy to excite Gain Medium. Gain Medium receives pump source excitation and generates photons from which a laser is amplified. Cavity is the place where photon characteristics (frequency, phase and direction) are regulated by controlling cavity oscillation to obtain high quality output light source.

Due to its unique reverse and forward piezoelectric effect, PZT is widely applied in various laser tunings. The following are several types of lasers that can use PZT for tuning:

Tunable Fiber Lasers:For small volume tunable fiber lasers, sheet or stacked PZT ceramics can be used, with a tuning range of approximately 3.3 microns. Additionally, by bonding PZT to fiber grating lasers and adjusting the driving voltage, wavelength tuning can be achieved.

Ring Cavity Fiber Lasers:Using PZT drivers, the length of the fiber grating in ring cavity fiber lasers can be changed to tune the output wavelength of the laser.

External Cavity Semiconductor Lasers:Based on Littrow structure external cavity semiconductor lasers, rapid continuous wavelength tuning can be achieved using PZT, with a tuning range of 10-20 GHz. Additionally, by establishing an atomic level closed-loop displacement control system using femtosecond frequency combs and Fabry-Perot interferometers, high precision tuning can also be achieved.

Tunable Single-Mode DBR Fiber Lasers: Single-mode DBR fiber lasers based on PZT stretching mechanism can effectively alleviate the jump mode phenomenon during frequency tuning, achieving a wider no-jump frequency tuning range.

Frequency Doublers: For example, in 1560nm laser frequency doubling research, by scanning the PZT voltage, at least 10GHz continuous tuning of 780nm doubled light frequency can be achieved.

Piezoelectric ceramics in the laser resonant cavity are mainly responsible for accurately controlling the length of the resonant cavity. Specifically, piezoelectric ceramics regulate the length of the resonant cavity through minute deformation, thereby stabilizing the frequency of the laser.

Piezoelectric ceramics are usually fixed on one mirror in the resonant cavity, such as a reflective mirror or a transmissive mirror. In some designs, piezoelectric ceramics are directly attached to the back of the reflective mirror to achieve precise control over the length of the cavity.

When a voltage is applied to the piezoelectric ceramics, it will undergo minute deformation. This deformation will cause a minute change in the length of the resonant cavity, resulting in a change in the frequency of the laser. By adjusting the voltage applied to the piezoelectric ceramics, the length of the resonant cavity can be precisely controlled to maintain stable frequency.

In dynamic stabilizing ring-shaped resonant cavities based on Nd:YAG lasers, piezoelectric ceramics are used to control the position of the mirrors to accurately regulate the length of the resonant cavity and tune the resonant frequency. In addition, in some high-power laser systems, such as doubling systems, a similar design is adopted using piezoelectric ceramics to control the length of the cavity to achieve stable green light output.

Use D/A card output non-uniform control voltage sequence to drive the piezoelectric ceramics power source to produce minute deformation and thereby control uniform change in the resonant cavity length. A single-chip microcomputer-based closed-loop control system can automatically find the optimal working state of the laser and maintain it at that state.

The selection of piezoelectric ceramics for laser systems involves multiple aspects, including their physical properties, accuracy requirements and compatibility with the laser system.

The micro-displacement driving principle of piezoelectric ceramics is the basis for controlling the length of the laser resonant cavity. By adjusting the deformation of the piezoelectric ceramics, the length of the laser resonant cavity can be accurately controlled to achieve stable and tunable laser frequencies.

Piezoelectric ceramics have extremely high resolution, which means that they can exhibit very high accuracy even at the smallest output signals from the drive power source.

The working temperature range of piezoelectric ceramics is typically between -25°C to 130°C, allowing them to operate in various environmental conditions. The driving voltage of piezoelectric ceramics can be from 0V to 150V, providing flexibility for different laser systems.

Many laser systems employ closed-loop control systems, which include microcontrollers, piezoelectric drive power sources, signal acquisition and processing circuits, and display circuits to automatically find and maintain the optimal operating state of the laser.

For example, a sub-nanometer level closed-loop displacement control system based on femtosecond optical frequency combs can achieve precise tuning of semiconductor lasers within their working frequency range.

To Achieve More Accurate Control, Many Laser Systems Use Closed-Loop Control Systems.

This system includes a microcontroller, piezoelectric drive power source, signal acquisition and processing circuit, and display circuit, which can automatically find the optimal operating state of the laser and maintain it. For example, a sub-nanometer level closed-loop displacement control system based on femtosecond optical frequency combs can achieve precise tuning of semiconductor lasers within their working frequency range.

Piezoelectric Department of YiNGUAN Focuses on the research, development, manufacturing and sales of precision positioning actuators and motion systems; which also is one of the few domestic high-tech enterprises that owns a complete product chain from piezoelectric ceramic materials to piezoelectric ceramic motors to Nano precision piezo-motion tables. The company has rich experiences in industrialization.

YiNGUAN provides stacked piezoelectric ceramics with millisecond response time and nanometer resolution, maximum displacement up to 180 micrometers, and resonant frequency up to 250 KHz, ensuring quick response and high precision control. YiNGUAN's self-developed stacked piezoelectric ceramics can produce large driving displacements at relatively low voltage.

The company has achieved mass production of piezoelectric ceramics with a wide range of specifications to meet various customer needs.

For different customers’ special requirements, YiNGUAN can provide customized packaging dimensions, voltage, stroke, and metal parts to meet mechanical stiffness and stability requirements.

Meanwhile, the company integrates strain gauges to achieve closed-loop control for customers’’ special needs. Self-developed drivers and controllers are optional to achieve product’s technology and cost advantages.

YiNGUAN has four service centers in China:

* Shanghai

* Suzhou

* Guangzhou

* Chengdu

These service centers can quickly respond to national customers' needs of technical upgrades, replacements, project development and maintenance.