Vibration isolation is a crucial supporting technology for large precision machining equipment, measurement instruments, nanomanufacturing foundation devices, biological gene operation devices, and large ultra-precision scientific experimental platforms, and it is also a signature technology of national advanced equipment manufacturing and testing capabilities.

In the microelectronics industry, the control requirements for ground vibrations are becoming increasingly high as silicon wafer processing linewidths continue to decrease. From 180nm to 45nm, 10nm, 7nm, and currently reaching 3nm in 2021.

In precise optical engineering, optical instrument resolution is also increasing, with stricter vibration environment requirements. Atomic force microscopes and scanning probe microscopes have vertical resolutions and horizontal resolutions of nanometer levels; scanning electron microscopes have vertical resolutions of 0.01nm and horizontal resolutions of 1nm; white light interferometers have vertical resolutions of 0.1nm. High-resolution micro experiments such as high-resolution microscopes, laser confocal microscopes, etc., also require optical vibration isolation platforms.

In MEMS technology fields, MEMS devices are widely used in measurement instruments, automotive electronics, and biomedical applications. Following the extension of MEMS concepts to nanometers, NEMS emerged in the late 20th century, requiring higher requirements for micromanufacturing equipment. These devices are highly sensitive to ground micro vibrations, which can lead to large errors in processing or testing results.

In precision mechanical manufacturing, optical vibration isolation platforms are used for precise mechanical manufacturing equipment and device vibration control.

In the field of photonics, optical vibration isolation platforms are commonly used to build small-scale optical paths.

Additionally, high-precision vibration isolation platforms are also required in metallurgy, navigation, non-destructive testing, precision chemical engineering, quantum optics, and nonlinear optics fields.

Overall, active optical vibration isolation tables have a wide range of applications, covering multiple aspects from industrial production to scientific research work.

Vibration isolation can be divided into two categories: passive vibration isolation and active vibration isolation, depending on whether the vibration system requires external energy support to operate normally.

In many application scenarios, a hybrid system combining passive and active components is adopted. By adding active control elements to the passive system, low-frequency vibrations are isolated using active control, while high-frequency vibrations are isolated by passive components.

Active vibration isolation refers to the process where a control strategy is applied based on real-time vibration signals detected during vibration control, which drives an actuator to apply an opposing force to the controlled object, achieving vibration suppression or elimination. Active vibration isolation is particularly suitable for low-frequency and high-precision applications.

Precise instruments and devices require micro-meter level amplitude tolerance and a wide frequency range for isolation, especially for low-frequency signals. Traditional passive vibration isolation technology cannot achieve this, only active vibration isolation can be used.

An active optical vibration isolation table is a device that uses electrical control to eliminate vibrations by applying a counteracting force. A sensor continuously monitors vibrations and an actuator produces an opposing force based on this information. This active vibration isolation platform allows for free selection of size and configuration, and can support larger instrument weights by adding more vibration modules.

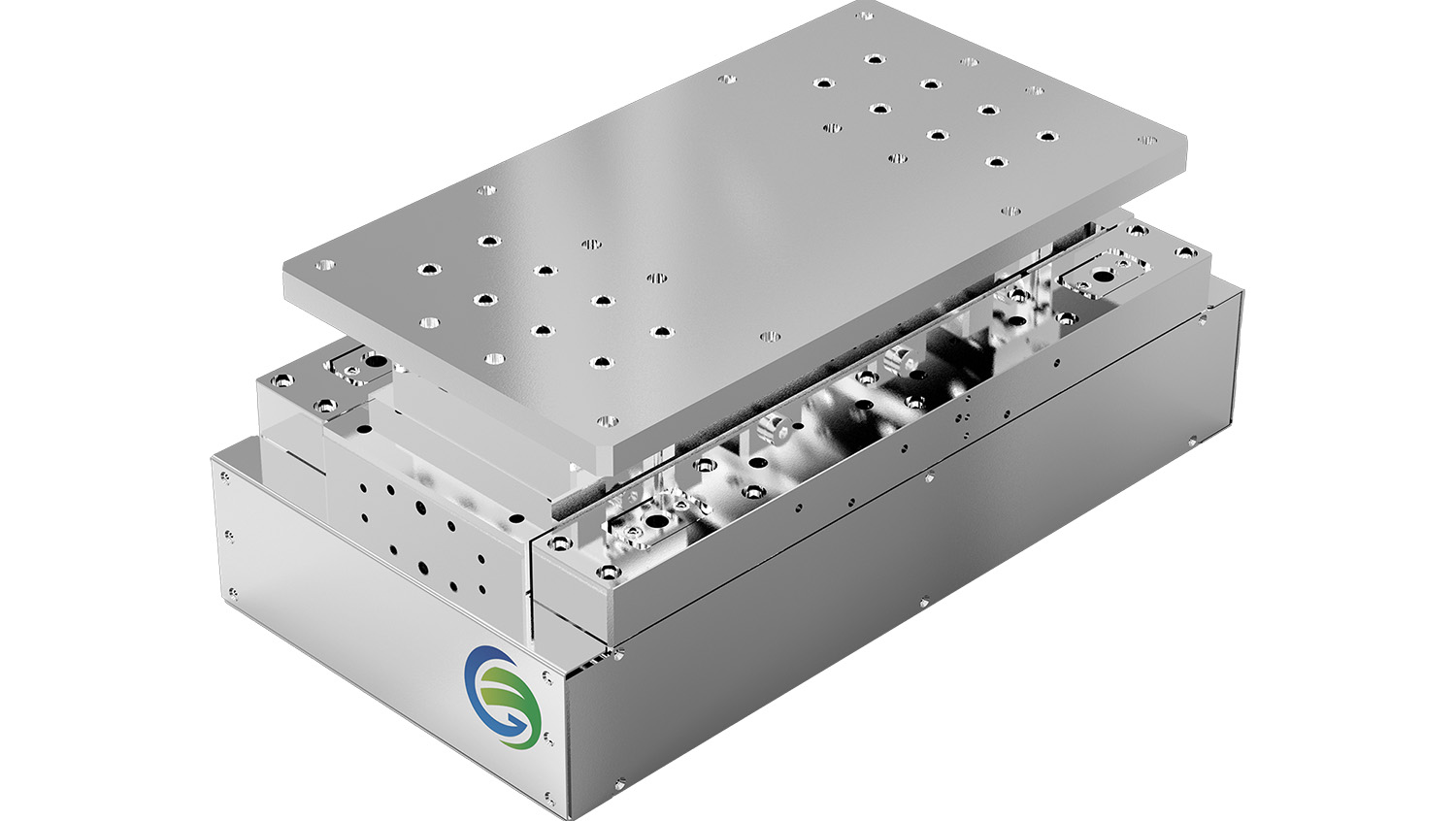

An active vibration isolation system includes a base frame, three (or four) active vibration isolators, and a load platform. The load platform is made of high-stiffness steel material with an equilateral triangle or rectangular shape. The base frame is fixed on the ground, while the isolators are connected to the base frame and the load platform is supported by the isolators.

Currently widely used actuators for active vibration isolation include pneumatic and hydraulic actuators, piezoelectric actuators, electromagnetic actuators (voice coil motor), and super magnetic actuators.

Suitable Frequency Range for Active Optical Vibration Isolation System is typically from 0.5 Hz to 200 Hz.

YiNGUAN provides active XZ vibration isolation platforms with load capacity ranging from 30kg to 1000kg. The vibration isolation system is based on YiNGUAN proprietary piezoelectric micro-step motor technology, which offers high stiffness, high response time and high accuracy.

The system can achieve dual functionality of motion positioning and vibration isolation in the XZ direction, suitable for active vibration control bandwidth of 1-100Hz.

- Dual Functionality: Positioning and Vibration Isolation

YiNGUAN's vibration isolation solution uses micro-step motors as core actuation components, enabling efficient vibration isolation and precise positioning to meet dual requirements.

- High Accuracy Initial Positioning

The system allows for accurate initial position setting, ensuring devices start at the desired location and increasing operational efficiency and accuracy.

- Self-Holding Ability

Even in power outage, the system maintains the current position, preventing position drift due to power fluctuations and ensuring continuous operation.

- Advantage over Traditional Drives

YiNGUAN's vibration isolation platforms outperform conventional drives (e.g. voice coil motors) with superior performance, overcoming traditional limitations.

YiNGUAN's proprietary micro-step motors are compact in size but can produce high driving forces, with standard specifications of 50N and 100N. High-force versions up to 300N are also available for release.

Key advantages:

High Driving Force: Micro-step motors can generate significant driving forces despite their small size.

Excellent Power Hold-Up: Micro-step motors have good power hold-up capabilities, suitable for precise instrument equipment applications.

Ultra-High Resolution: Drives can achieve resolution as low as 0.5nm.

Advantages of YiNGUAN's Micro-Step Motors

Compact and High Load Capacity: Suitable for desktop active vibration isolation applications, especially for high-precision equipment floor isolation.

Easy Installation: Easy to install on devices due to compact size and simple design.

Prevention of Shock Damage: Good power hold-up capabilities prevent shock damage caused by unexpected power failures.

Customization: Available in customized specifications: interfaces, installation methods, loads, and vibration control algorithms.

( Latest industry technical data comes from website)