Glue dispensing equipment utilizes glue dispensing technology, combining mechanical structure design, motion algorithm, image vision, etc., to achieve high-precision, efficient, and stable output of adhesive. From the perspective of the smart glue dispensing industry chain, the upstream industry includes electronic components, mechanical parts, system integration; the midstream is fluid control device production and manufacturing, mainly including glue dispensing machines, coating machines, etc.; the downstream is widely applied in consumer electronics, new energy vehicles, photovoltaics, semiconductor industries.

According to data from International Semiconductor Industry Association (SEMI) and related sources, the global market size of glue dispensing machines is predicted to reach 9.03 billion US dollars in 2022, with Asia-Pacific accounting for 53%. By 2028, it is expected to reach 10.68 billion US dollars. The market space for glue dispensing machines is relatively broad.

The value of consumer electronics continues to rise, and the market capacity of glue dispensing equipment is expected to increase from 133.3 billion yuan in 2020 to 191.8 billion yuan by 2025; new energy vehicles are expected to reach 1.15 million units in 2025, driving demand for glue dispensing. In photovoltaics, the production capacity of photovoltaic components is expected to exceed 400 GW in 2023, with high growth driving market capacity from 9.8 billion yuan in 2020 to 17.2 billion yuan by 2025.

Position accuracy, repeat accuracy, point glue speed, etc., are key technical parameters affecting the stability, reliability, and safety of terminal products; they are also crucial factors influencing whether precision smart manufacturing product processing technology can be implemented.

The performance of glue dispensing equipment is determined by both glue core components and glue machine platform. Glue core components include point glue valve performance indicators, including minimum point glue diameter, viscosity range, continuous running frequency, consistency error; the glue machine platform includes position accuracy, motion speed, XY axis positioning accuracy, XY axis repeat accuracy, point glue speed, maximum acceleration, etc.

Among fluid control equipment, valve actuators are core components, mainly applied in glue dispensing machines and coating machines. The performance of valves will affect technical parameters of glue dispensing machines.

Early automatic glue dispensing equipment used contact-type needle glue guns, which had issues such as stringing, needle breakage, and low accuracy. After that, electromagnetic drive valves emerged, forming a new type of non-contact glue dispensing (also known as spray glue). Spray glue has characteristics such as no contact with workpieces, no Z-axis movement, fast point glue speed, high accuracy, and good consistency.

However, the working frequency of electromagnetic drive valves is limited to around 200 Hz, which restricts point glue accuracy and speed. With the rapid development of 3C electronic products represented by smartphones, the electronics manufacturing industry has raised higher demands for glue dispensing precision and efficiency. Foreign brands such as American Noliac, German Mikrosystem, German Marcotec, and Japanese Fujikura have entered the market with piezoelectric spray valves.

Piezoelectric spray valves also belong to non-contact glue dispensing and have characteristics such as improved point glue accuracy and speed compared to electromagnetic drive valves, as well as good consistency, easy maintenance, and testing. Based on these advantages, piezoelectric spray valves have begun to be widely used.

The continuous precision development of manufacturing industries has brought mature market conditions and a broad market space for piezoelectric spray valves. For example, in semiconductor manufacturing, piezoelectric ultrasonic flow control does not produce magnetic fields and will not damage deionized water properties, which can be applied to etching machines, thin film deposition equipment, vacuum coating equipment, etc.

With the appearance of TWS headphones, smart watches, and other wearable products as well as rapid development of artificial intelligence and 5G technologies, electronic components are continuing to miniaturize and integrate, and there is a growing demand for high-precision glue packaging. Piezoelectric spray valves are expected to become the mainstream glue dispensing method in precise electronics manufacturing fields such as 3C electronics, new energy batteries, semiconductors, etc.

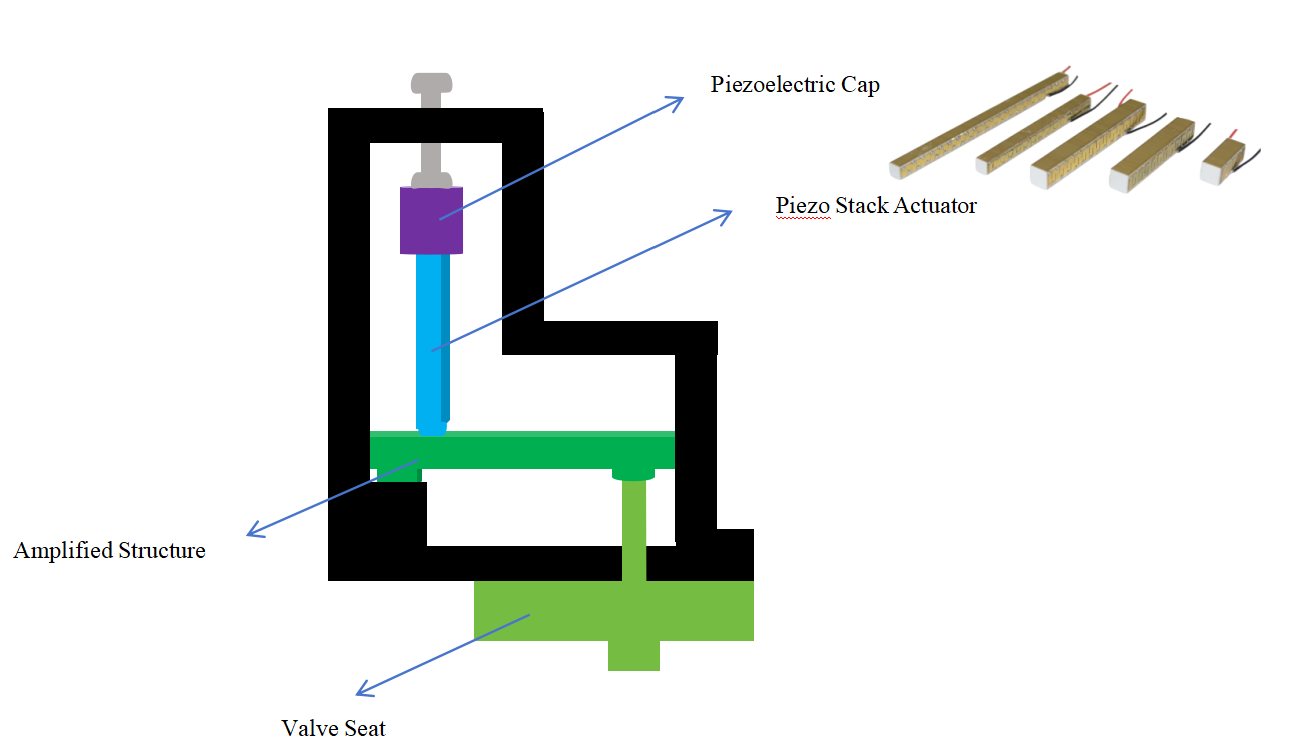

(Piezoelectric spray valve’s structure)

|

Project Type |

Piezoelectric Drive |

Electromagnetic Drive |

|

Conversion Principle |

Utilize inverse piezoelectric effect to convert electrical energy into mechanical energy. |

Utilize electromagnetic induction principle to convert electrical energy into mechanical energy. |

|

Electrical Properties |

Capacitive type |

Inductive type |

|

Highest Frequency Response |

Greater than 50,000Hz |

Less than 10,000Hz |

|

Displacement Resolution |

Minimum of 1nm |

Greater than 100nm |

|

Response Time |

Less than 0.1ms |

Greater than 10ms |

|

Electrical Driving Characteristics |

High voltage, low current |

Low voltage, high current |

(Comparative analysis of the characteristics of Piezoelectric Drive and Electromagnetic Drive technology)

|

Project |

Piezoelectric Drive |

Electromagnetic Drive |

|

Output Power |

Small, suitable for micro-power or small power driving |

Large to tens of watts, small to several milliwatts driving |

|

Device Structure |

Easy to make miniature or small structure, flexible design |

Large volume, many components, complex structure, weak driving capability in miniaturized form |

|

Power Consumption |

Low power consumption, little heat generation |

High power consumption and heat generation |

|

Safety |

No magnetic field, electric spark, resistant to high temperature and corrosion,suitable for explosive or flammable environments |

Generates external magnetic interference, electric sparks in some cases, not suitable for explosive or flammable environments,explosion-proof coils or other measures are needed to improve safety.

|

|

Noise |

Low noise, suitable for medical environments |

High noise |

(Comparative analysis of the application characteristics of Piezoelectric Drive and Electromagnetic Drive)

Piezoelectric spray valves commonly use a piezoelectric stacked driver structure, which has the advantages of high output force to the load and short response time. However, it also has the disadvantages of high driving voltage and small displacement, requiring a displacement amplification mechanism to be used in conjunction.

The company's piezoelectric ceramics have achieved mass production and offer a wide range of product specifications and varieties to match different Point Glue Valve structural designs.

To meet clients' customized integration requirements, YiNGUAN can customize packaging dimensions, voltages, strokes, and metal terminals, ensuring mechanical stiffness and stability to ensure the reliability and long-term performance of the Point Glue Valve.