High stiffness, high precision guide

Consistent design of cable disturbing force

Infinition angle motion with optional rotation angle hard limit

Vacuum feed-through to the chuck level, support for multi-airway air supply

Rotation velocity up to 150rpm

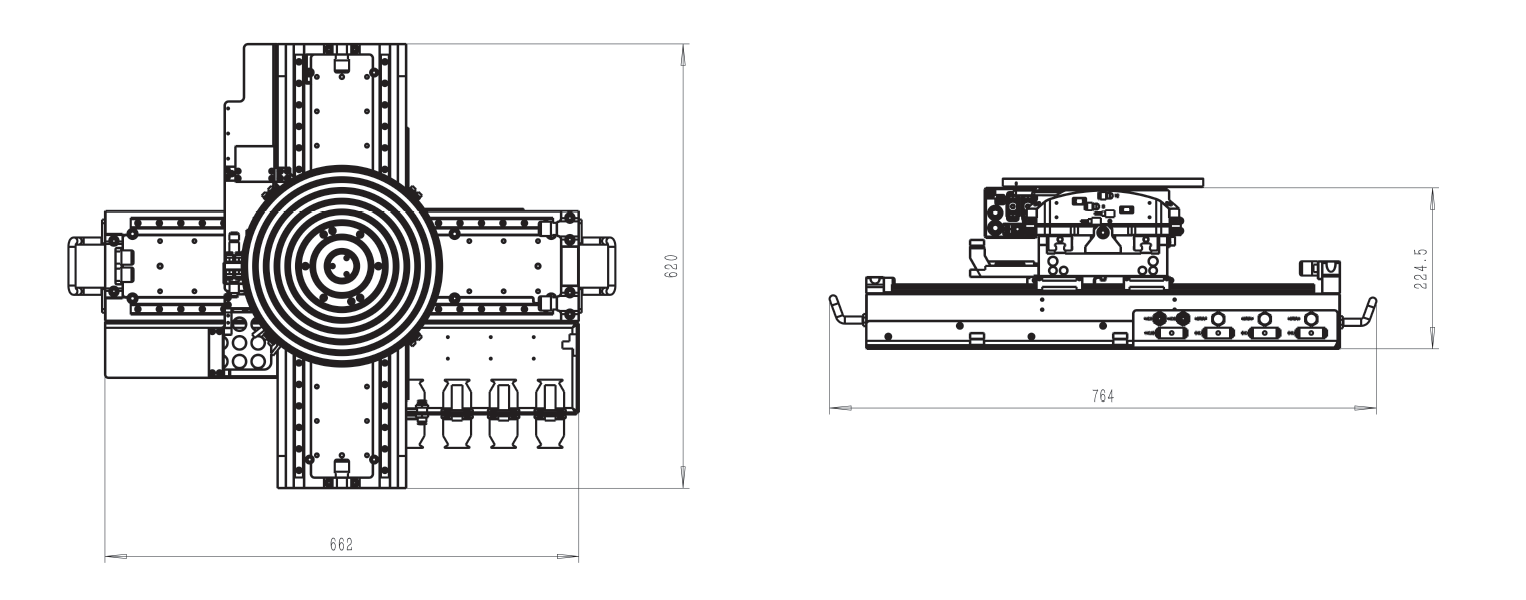

The stage adopts modularization, low-profile, orthogonality design, the RD-180 Stage standard module is integrated on top of the cross platform L2S125 for high precision, high stiffness motion of X, Y and Z axis with 3 degrees of freedom.

The RD-180 adopts low-profile design. High-precision, high-stiffness infinition rotation in the T axis.

The L2S125 adopts integration, orthogonality design with a compact, low-profile. High-precision, high-stiffness linear motion in horizontal X/Y axis with 2 degrees of freedom.

*Interface dimensions from LST190 in the middle stroke

|

|

LST190-365 |

||

|

Axes name |

X |

Y |

T |

|

Travel range |

365 mm |

365 mm |

360°,Infinite |

|

Max. velocity |

1 m/s |

1 m/s |

900°/s |

|

Max. acceleration |

10 m/s² |

10 m/s² |

6280°/s² |

|

Accuracy_indicative value |

±10 μm |

±10 μm |

|

|

Accuracy_calibration value |

±1 μm |

±1 μm |

±3 arcsec |

|

Bidirectional repeatability |

±0.5μm |

±0.5μm |

±2arcsec |

|

Straightness |

±2 μm over range |

±2 μm over range |

|

|

Pitch |

±5 arcsec |

±10 arcsec |

|

|

Roll |

±5 arcsec |

±10 arcsec |

|

|

Yaw |

±10 arcsec |

±10 arcsec |

|

|

Orthogonality |

±15 arcsec |

|

|

|

Axial & Radial runout |

NA |

±1.5 μm |

|

|

Position stability(3σ)* |

±2 nm |

±2 nm |

±0.072 arcsec |

|

Move1:10μm within±100nm* |

50 ms |

50 ms |

|

|

Move2:25mm within±100nm* |

140 ms |

140 ms |

|

|

Move3:80mm within±100nm* |

170 ms |

170 ms |

|

|

Move4:1deg within±40μdeg |

|

|

100 ms |

|

Move5:180deg within±40μdeg |

|

|

500 ms |

|

Mechanical properties |

|

|

|

|

Moving mass (without payload) |

12 Kg |

28 Kg |

0.02022 Kg•m² |

|

Max. load |

2 Kg (customizable) |

||

|

Stage mass |

50 Kg |

||

|

Dimensions |

764×620×224.5 mm (middle of stroke) |

||

*Technical data specified with 8μm pitch encoder and under active vibration isolation environment.

The series is configured with options that can be selected based on the user's actual application. Options include encoders, chuck air supply, and more. X-axis base can be changed to marble base according to customer's requirement, which can provide higher positioning accuracy.

|

Table 1 Encoder Options |

|

|

-S1 |

Standard, Renishaw Encoder |

|

-S2 |

High-end model, Heidenhain encoder |

|

Table 2 Chuck Air Supply Options |

|

|

-C1 |

Chuck with single air supply |

|

-C2 |

Chuck with dual air supply |

|

-C3 |

Chuck with triple air supply |