High stiffness linear guide

Non-contact direct-drive linear motor drive for high dynamic response

Active air/water cooling design

Maglev gravity compensation technology in vertical for high positioning accuracy

High stiffness, high precision guide

Ultra-thin, lightweight design

Modularization design

Vertical mechanical travel up to 30mm

360°rotation, no tubing wrapping

12', 8', 6' wafer applicable

Active air/water cooling design

Wafer warpage up to 0.7mm

Rotation velocity up to 150rpm

The stage adopts highly modularization, ultra-thin design. High-precision and high-stiffness linear and rotary motions with 3 degrees of freedom in X, Z and T axes.

The vertical uses the large-stroke maglev gravity compensation technology, which has the function of reducing the load of the vertical motor and greatly improving the vertical motion performance and lifetime.

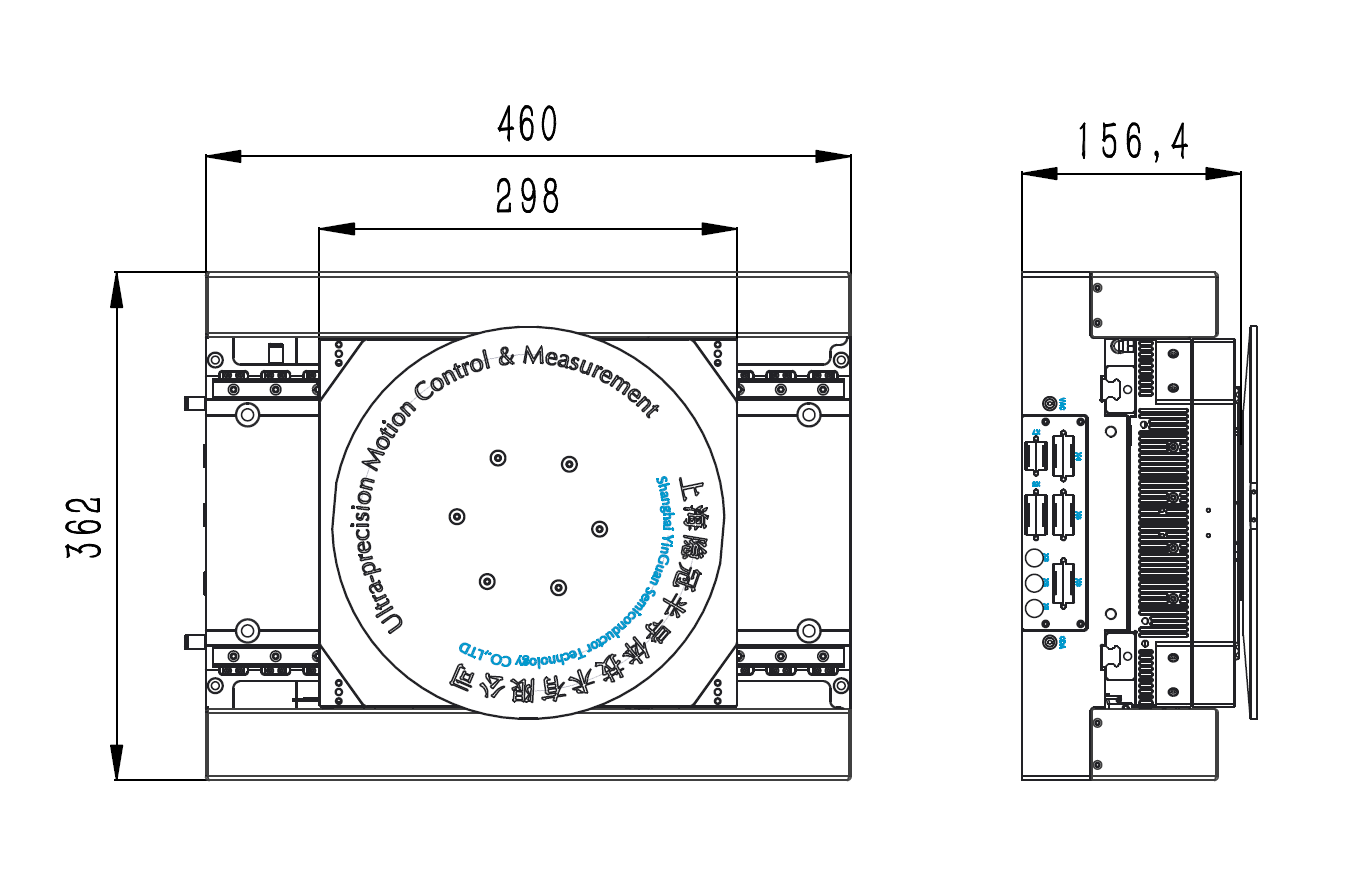

*Interface dimensions from PS150 in the lower limit

|

|

PS150-155 |

||

|

Axes name |

X |

Z |

T |

|

Travel range |

155 mm |

25 mm |

360°, Infinite |

|

Max. velocity |

400 mm/s |

40 mm/s |

900°/s |

|

Max. acceleration |

4m/s² |

1m/s² |

6280°/s² |

|

Accuracy |

±1 μm |

±0.5 μm/1mm |

±3 arcsec |

|

Bidirectional repeatability |

±0.5 μm |

±0.3 μm/1mm |

±2 arcsec |

|

Straightness |

6 μm |

NA |

NA |

|

Pitch |

±20 μrad(4.5arcsec) |

NA |

NA |

|

Roll |

±20 μrad(4.5arcsec) |

NA |

NA |

|

Yaw |

±20 μrad(4.5arcsec) |

NA |

NA |

|

Axial runout |

NA |

NA |

±2 μm |

|

Radial runout |

NA |

NA |

±2 μm |

|

Mechanical properties |

|

|

|

|

Moving mass (without payload) |

12 Kg |

5.4 Kg |

NA |

|

Inertia (No load) |

0.00401 Kg•m² |

||

|

Max. load |

2 Kg (customizable) |

||

|

Stage mass |

44 Kg |

||

|

Dimensions |

460mm×362mm×156.4mm (vertical lower limit) |

||

|

Material |

Aviation aluminum, anodized |

||

The series is configured with options that can be selected based on the user's actual application. Options include encoders, guide, and more.

|

Table 1 Encoder Options |

|

|

-S1 |

Incremental analog optical encoder, 1Vpp, 20μm Pitch |

|

-S2 |

Incremental digital optical encoder, TTL, 20μm Pitch |

|

-S3 |

Absolute optical encoder, BISS-C, 20μm Pitch |

|

Table 2 Vertical Mechanical Stroke Options |

|

|

-10 |

with vertical mechanical stroke of 10mm |

|

-20 |

with vertical mechanical stroke of 20mm |

|

-25 |

with vertical mechanical stroke of 25mm |