The stage adopts low-profile design. The vertical uses the large-stroke maglev gravity compensation technology, which has the function of reducing the load of the vertical motor and greatly improving the vertical motion performance and lifetime. High-precision up- and -down positioning is possible. The vertical provides high stiffness mechanical bearing and high-performance air-bearing options. Air-bearing provides higher bidirectional repeatability.

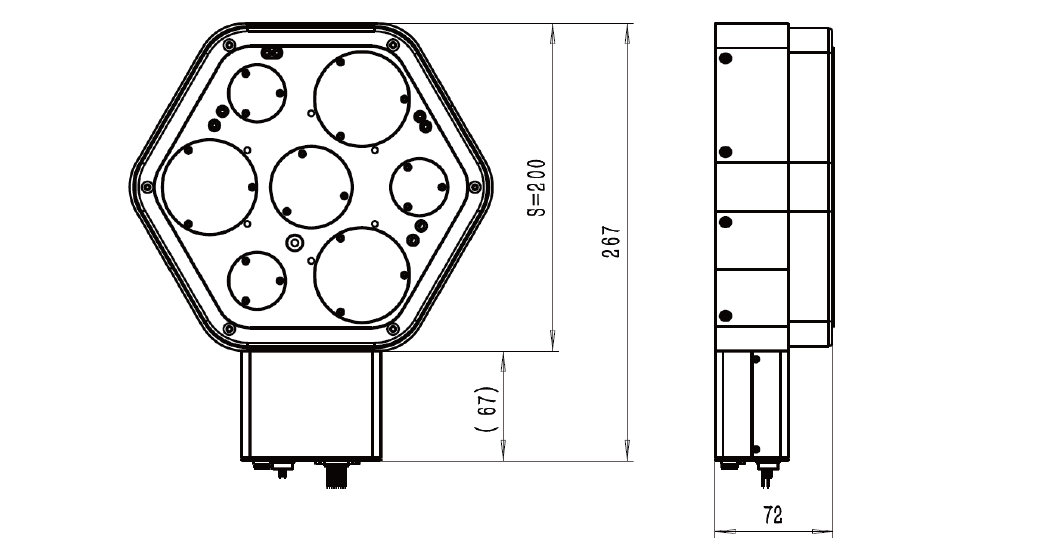

*Interface dimensions from MZM200 in the middle of vertical stroke

|

|

MZM200-10 |

|

Travel range |

10 mm |

|

Max. velocity |

100 mm/s |

|

Max. acceleration |

2 m/s² |

|

Accuracy |

±0.5 μm/1 mm |

|

Bidirectional repeatability |

±0.3 μm/1mm |

|

Position stability (3σ) |

±50 nm |

|

Straightness |

2 μm |

|

Pitch |

100 μrad (21 arcsec) |

|

Roll |

100 μrad (21 arcsec) |

|

Yaw |

100 μrad (21arcsec) |

| Mechanical properties | |

|

Moving mass (without payload) |

1.8 Kg |

|

Max. load |

6.2 Kg |

|

Stage mass |

3.5 Kg |

|

Dimensions |

S200 mm×72 mm |

|

Material |

Aviation aluminum, black anodized |

The series is configured with options that can be selected based on the user's actual application. Options include travel, encoder, guide, and more.

|

Table 1 Travel Options |

|

|

-5 |

5mm travel displacement platform with ring motor and limit |

|

-10 |

10mm travel displacement platform with ring motor and limit |

|

-25 |

25mm travel displacement platform with ring motor and limit |

|

Table 2 Encoder Options |

|

|

-S1 |

Incremental analog optical encoder, 1Vpp |

|

-S2 |

Incremental digital optical encoder, RS422 |

|

-S3 |

Absolute optical encoder, BISS |

|

Table 3 Guide Options |

|

|

-G1 |

High-stiffness mechanical guide |

|

-G2 |

High-performance air-bearing guide |