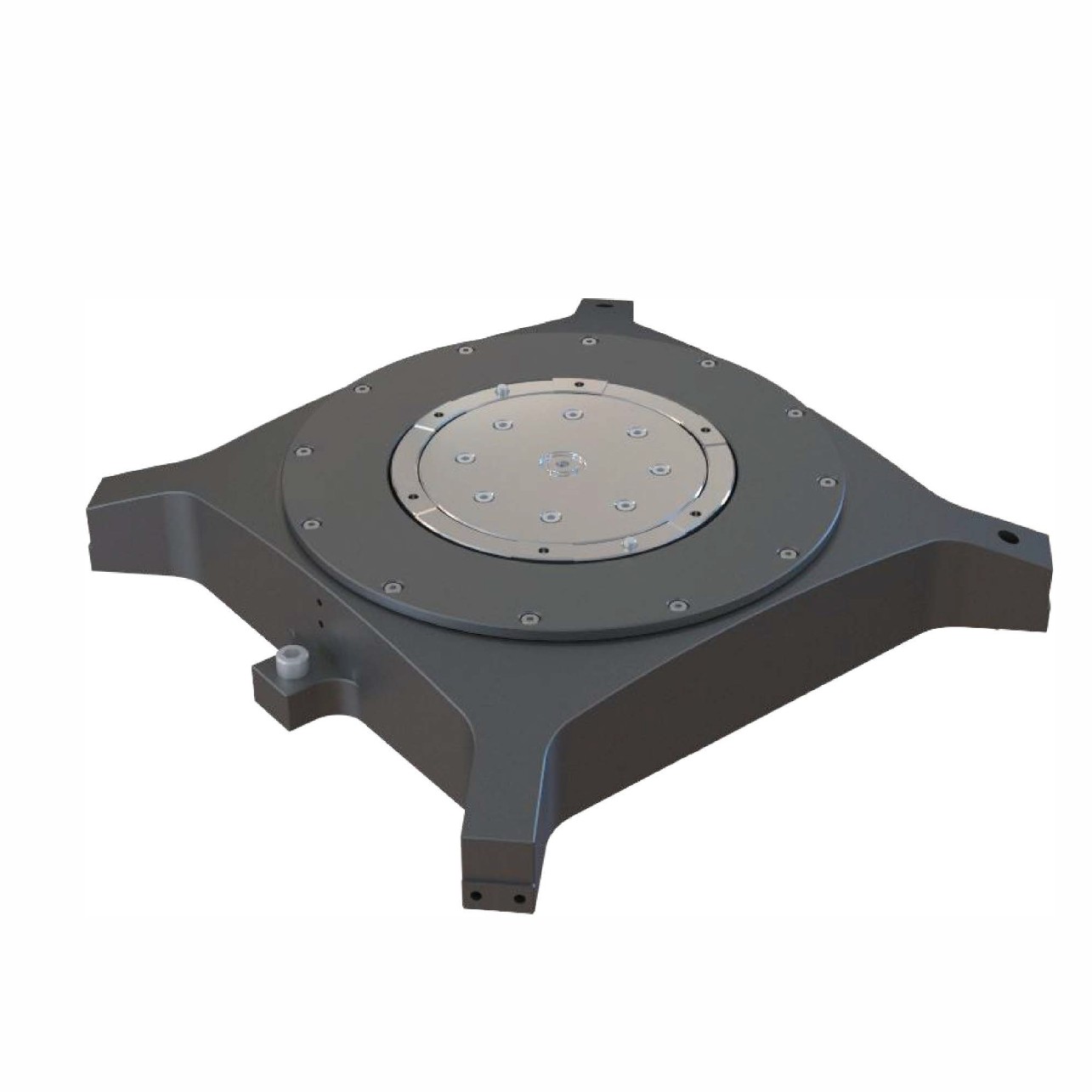

The stage adopts low-profile design. High-precision, high-stiffness, infinition rotation in the T axis.

*Interface dimensions from RD180

|

|

RD180-00 |

|

Accuracy_indicative value* |

±30 arcsec |

|

Accuracy_calibration value* |

±3 arcsec |

|

Bidirectional repeatability* |

±2 arcsec |

|

Axial runout |

±3 μm |

|

Radial runout |

±3.5 μm |

|

Tilt error motion |

10 arcsec |

|

Continuous torque |

2.4 N·m |

|

Max. velocity |

150 rpm |

|

Position stability(3σ)* |

±0.072 arcsec |

|

Move1:1 deg within±40μdeg* |

100 ms |

|

Move2:180 deg within±40μdeg* |

500 ms |

|

Mechanical properties |

|

|

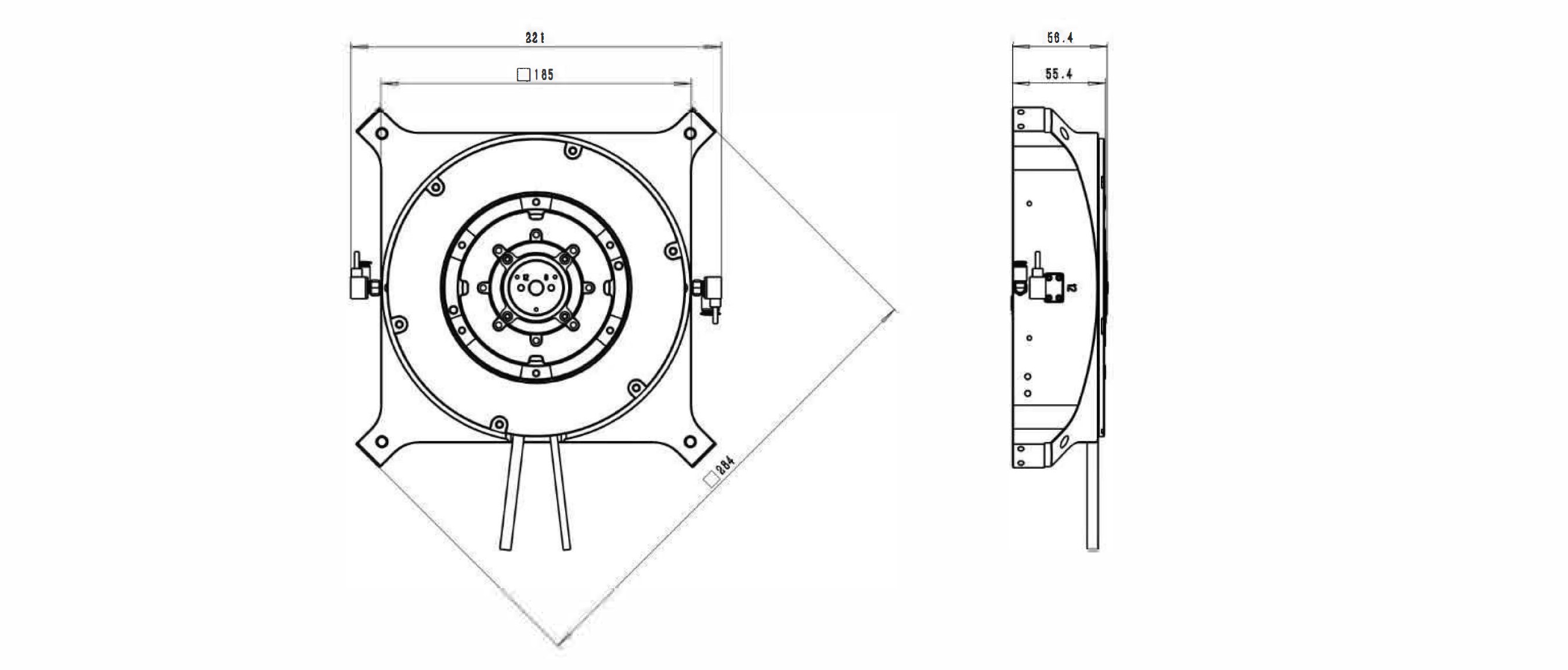

Dimensions |

284 mm×284 mm |

|

Max. load_Axial |

7 Kg |

|

Max. load_Radial |

3 Kg |

|

Inertia (No load) |

0.00038 Kg•m² |

*Technical data specified with 20μm pitch encoder and under active vibration isolation environment.

The series is configured with options that can be selected based on the user's actual application. Options include encoder, Chuck air supply, control system and more.

| Table 1 Encoder Options | |

|

-S1 |

Standard,Renishaw Encoder |

|

-S2 |

High-end model, Heidenhain encoder |

|

Table 2 Chuck Air Supply Options |

|

|

-C1 |

Chuck with single air supply |

|

-C2 |

Chuck with dual air supply |

|

-C3 |

Chuck with triple air supply |