Haptic Feedback Actuators: A New Blue Ocean in a Multi-Billion Dollar Market

The rapid development of fields like smart terminals, virtual/augmented reality (VR/AR), automotive electronics, and medical devices has positioned haptic feedback technology as a core driver for upgrading human-machine interaction experiences. According to market data, the global haptic feedback actuator market reached $1.2 billion in 2022 and is projected to grow to $3.5 billion by 2030, representing a compound annual growth rate (CAGR) of 14.5%.

Within existing markets, piezoelectric ceramic haptic actuators are progressively replacing traditional electromagnetic or linear motor solutions, becoming the preferred technology for high-precision, high-responsiveness scenarios:

√ Consumer Electronics: Smartphones, game controllers, and wearables enhance immersion through haptic feedback (e.g., Apple's Taptic Engine).

√ Medical & Industrial: Surgical robots and remote-operated devices rely on precise haptic simulation.

√ Automotive Electronics: The rise of smart electric vehicles (EVs) drives new demand.

Traditional ICE vehicles rarely incorporate haptic feedback, while smart cockpits (central touchscreens, steering wheel vibrations) and ADAS systems (safety alerts) are experiencing rapid growth alongside EV adoption.

√ AR/VR: Pure greenfield market with breakthrough potential.

Current penetration of devices like VR gloves and haptic suits remains low, but concepts like the metaverse and spatial computing are accelerating hardware innovation. Piezoelectric ceramics are becoming essential due to their high response speed.

Core Advantages of Piezoelectric Actuators: Why They Represent the Future Trend

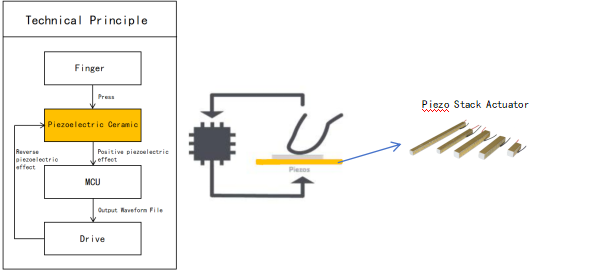

Piezoelectric ceramics leverage the inverse piezoelectric effect (mechanical deformation under applied electric field) to achieve nanometer-scale displacement control and millisecond-level response speeds. Key advantages over traditional technologies include:

√ Ultra-High Response Speed: Meets real-time interaction demands for VR/AR, eliminating latency.

√ Precise Force Control: Enables diverse tactile simulations from subtle vibrations to high-frequency impacts (e.g., taps, presses, texture feedback).

√ Low Power Consumption & Long Lifespan: Eliminates electromagnetic coil heating issues, significantly reduces power draw, and offers superior longevity.

√ Miniaturization: Significantly smaller form factors enable integration into ultra-thin devices and precision instruments.

Piezoelectric Ceramic Selection Guide: Key Parameters & Application Matching

In haptic applications, piezoelectric ceramic performance directly determines the end-user experience. Selection must prioritize these core parameters:

√ Quasi-Static Piezoelectric Coefficient (d33 pC/N)

Definition: Measures charge generation on electrodes under applied force (sensing parameter), indicating force sensitivity.

Selection Guideline: Higher d33 values (e.g., ≥600 pC/N) indicate greater force sensitivity and stronger output signals under low-force conditions (e.g., automotive touchscreens).

√ *Dynamic Piezoelectric Coefficient(d33* pm/V)

Definition: Measures strain generation per unit applied voltage (actuation parameter).

Selection Guideline: Larger d33* values yield greater deformation per volt, producing stronger vibration perception at equivalent frequencies. Essential for high-intensity vibration feedback scenarios.

√ Electromechanical Coupling Coefficient (k31)

Definition: Measures energy conversion efficiency between electrical and mechanical domains, impacting response speed and power consumption.

Recommended Value: k31 > 0.35 ensures high energy utilization efficiency.

√ Frequency Response Range

Typical Requirement: 50Hz–500Hz to cover the human tactile sensitivity range; avoid resonant peak shifts.

Optimization: Multi-layer stack designs broaden bandwidth for complex waveform output.

√ Temperature Stability

Challenge: Piezoelectric properties fluctuate with temperature (d33 temp. coefficient should be ≤ -2%/°C).

Solutions: Develop high-Curie-temperature piezoelectrics with large strain output and enhanced stability; or implement compensation circuits.

√ Durability & Reliability

Test Standards: <10% performance degradation after 10^9 cycles; pass 85°C/85% RH (dual 85) testing.

Conclusion: Technology Empowering Experience – Piezoelectric Ceramics Usher in a New Era of Haptic Interaction

From subtle smartphone vibrations to precise force feedback in surgical robots, piezoelectric ceramics are redefining the boundaries of touch. Facing billion-dollar market opportunities, selecting the right materials and optimizing designs will be key for companies to succeed.

Take Action Now:

If you are seeking high-performance piezoelectric ceramic solutions or require customized haptic feedback modules, contact our technical team! We offer end-to-end services—from material selection and structural design to mass production support—helping you secure technological leadership in human-machine interaction.