The stage is manufactured with materials that meet ultra-high vacuum standards and special processes in IS06 cleanrooms, ensuring that it can be used in ultra-high vacuum environments of 10-5Pa and below. While realizing high-precision and high-stiffness XY motion, it also ensures the thermal management and magnetic shielding needs in the vacuum environment.

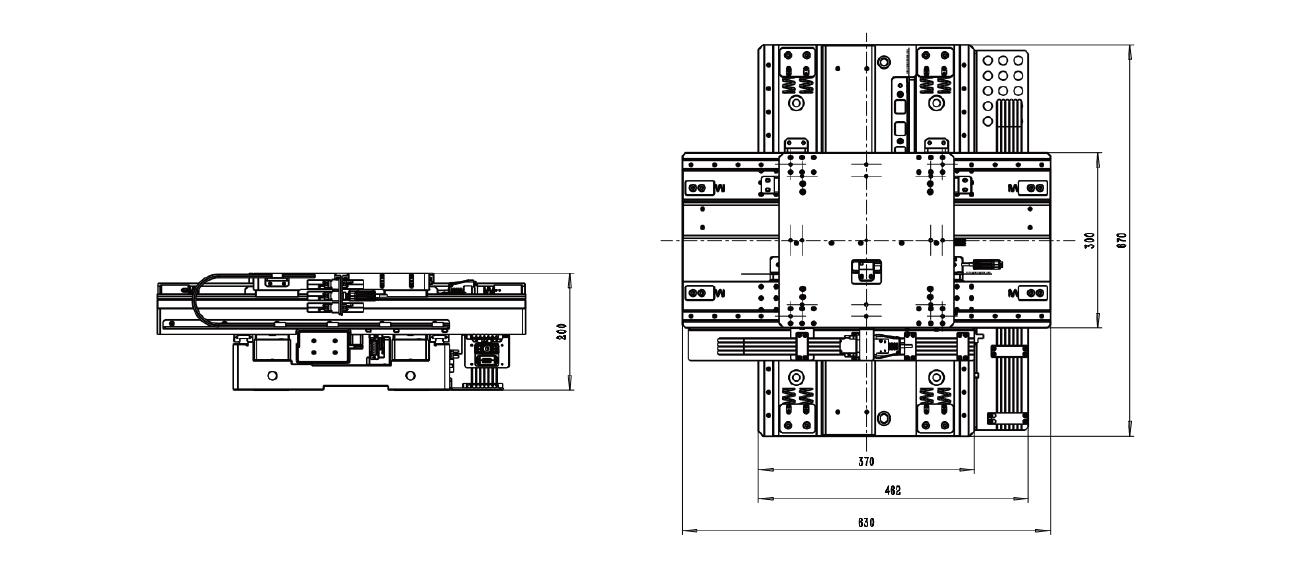

*Interface dimensions from VLS200

|

|

VLS200-08 |

VLS200-12 |

|||

|

Axes name |

X |

Y |

X |

Y |

|

|

Travel range |

300 mm |

220 mm |

400 mm |

320 mm |

|

|

Max. velocity |

0.35 m/s |

||||

|

Max. acceleration |

0.4 g |

||||

|

Accuracy |

±0.5 μm |

±0.5 μm |

±0.5 μm |

±0.5 μm |

|

|

Bidirectional repeatability |

±0.25 μm |

±0.25 μm |

±0.25 μm |

±0.25 μm |

|

|

Position stability(3σ)* |

±5 nm |

±5 nm |

±5 nm |

±5 nm |

|

|

Velocity stability* |

<0.1% |

<0.1% |

<0.1% |

<0.1% |

|

|

Straightness |

4 μm |

4 μm |

4 μm |

4 μm |

|

|

Pitch |

<10 arcsec |

<10 arcsec |

<10 arcsec |

<10 arcsec |

|

|

Yaw |

<10 arcsec |

<10 arcsec |

<10 arcsec |

<10 arcsec |

|

|

Mechanical properties |

|||||

|

Moving mass (without payload) |

52 Kg |

7 Kg |

53.5 Kg |

9 Kg |

|

|

Max. load |

13.5 Kg |

13.5 Kg |

|||

|

Stage mass |

100 Kg |

145 Kg |

|||

|

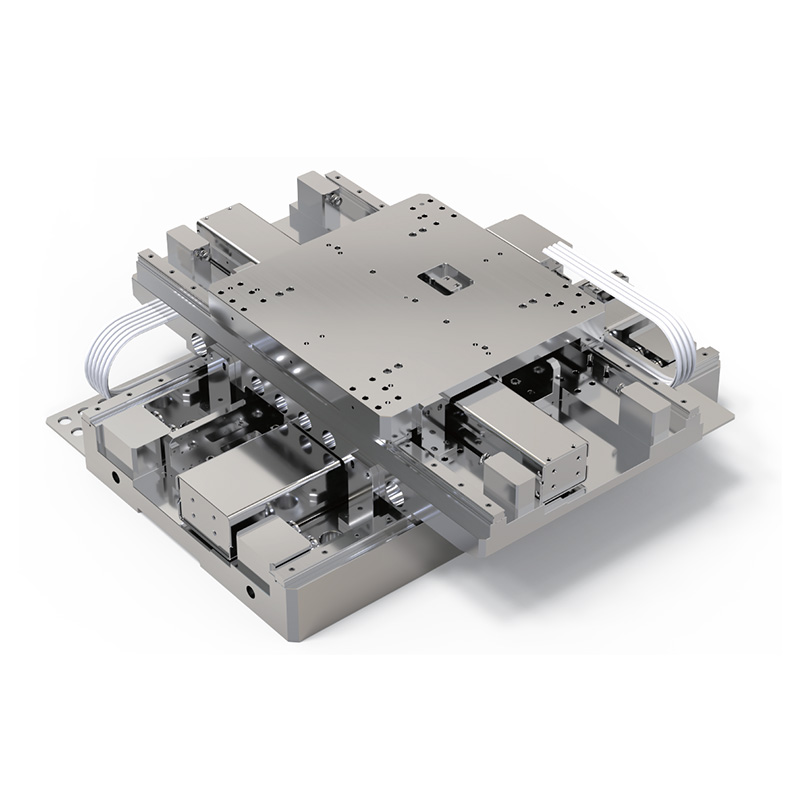

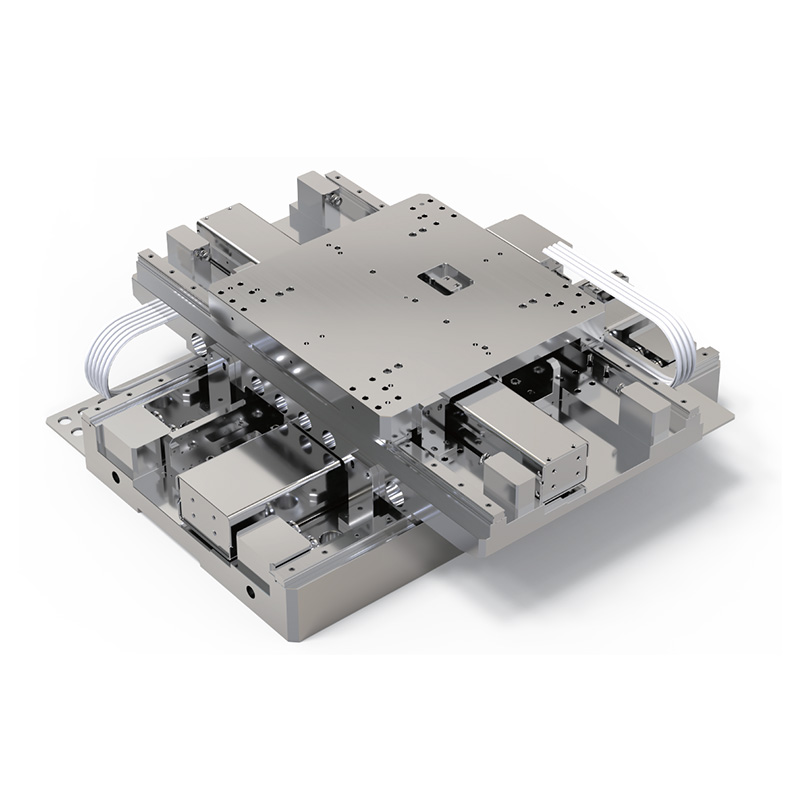

Dimensions |

670 mm×630 mm×200 mm |

810mm ×714 mm×200 mm |

|||

|

Material |

Aluminum alloy |

||||

*Technical data specified under non-active vibration damping environment.

The series is configured with options that can be selected based on the user's actual application. Options include encoders, control system, and more.

|

Table 1 Guide Options |

|

|

-G1 |

Normal linear guide for UHV |

|

-G2 |

Non-magnetic linear guide for UHV |